The Future of Metal Fabrication: Trends to Watch

Introduction to Metal Fabrication's Future

The metal fabrication industry is on the brink of a significant transformation. As technology continues to evolve, so do the methods and processes involved in metal fabrication. With emerging trends and innovations, the future of metal fabrication promises increased efficiency, precision, and sustainability.

In this blog post, we'll explore the key trends shaping the future of metal fabrication. From automation to sustainability, these advancements are set to revolutionize the industry.

Automation and Robotics

One of the most impactful trends in metal fabrication is the integration of automation and robotics. These technologies are streamlining production processes, reducing human error, and increasing productivity. Automated machinery can handle repetitive tasks with precision, allowing human workers to focus on more complex and creative aspects of fabrication.

Robots equipped with advanced sensors and AI capabilities are being used for tasks such as welding, cutting, and assembly. This not only speeds up production but also improves safety by reducing the need for human intervention in hazardous environments.

The Role of AI in Metal Fabrication

Artificial Intelligence (AI) is another game-changer in the metal fabrication industry. AI systems can analyze vast amounts of data to optimize production processes, predict maintenance needs, and improve quality control. By learning from past production data, AI can provide insights that lead to better decision-making and enhanced operational efficiency.

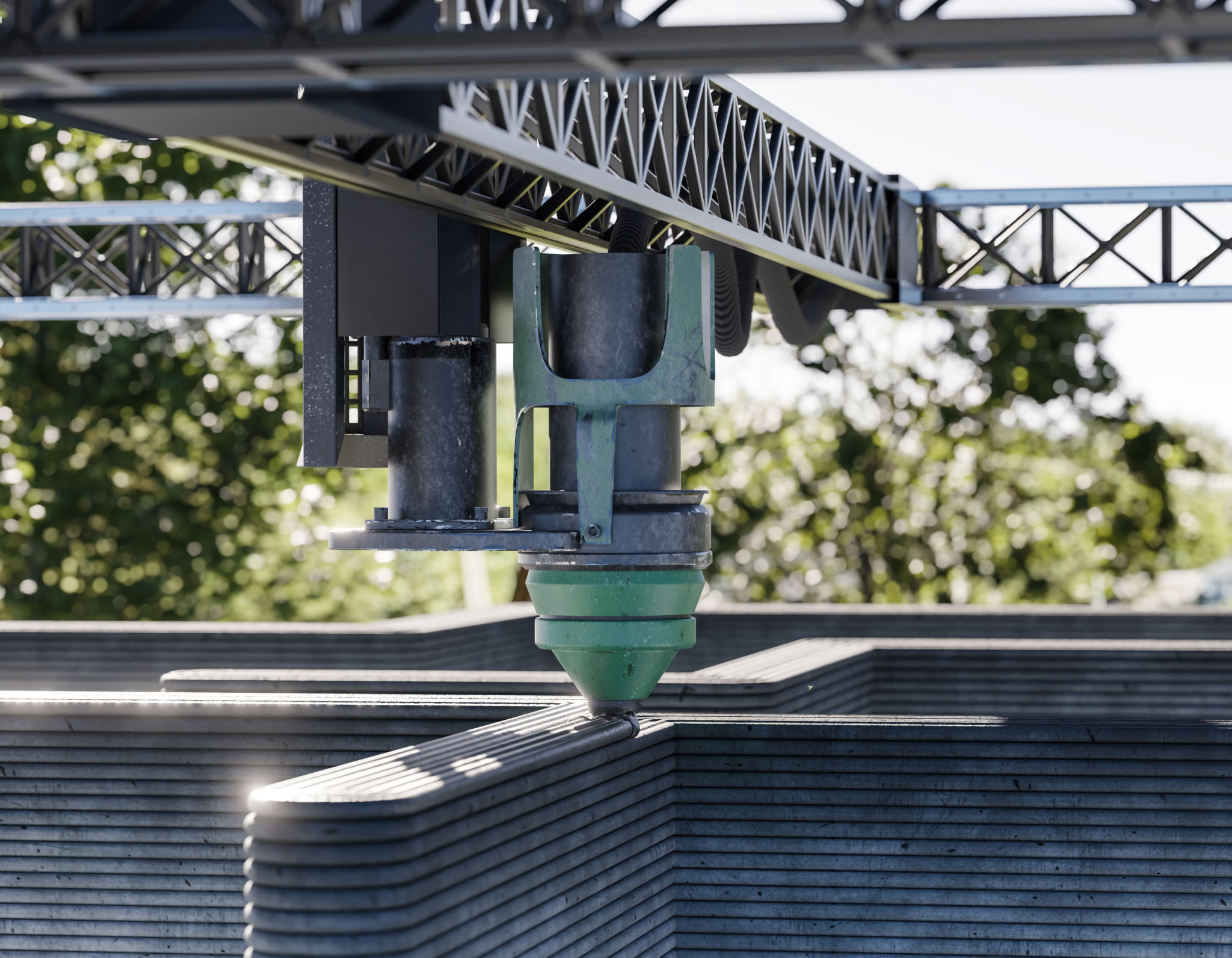

Advancements in 3D Printing

3D printing, or additive manufacturing, is increasingly being adopted in metal fabrication. This technology allows for the creation of complex geometries that were previously impossible or cost-prohibitive using traditional methods. With 3D printing, manufacturers can produce parts on-demand, reducing waste and inventory costs.

The ability to quickly prototype and iterate designs is another advantage of 3D printing. This accelerates the product development cycle and enables more customized solutions for clients.

Sustainability and Eco-Friendly Practices

As environmental concerns grow, the metal fabrication industry is seeking ways to reduce its ecological footprint. Implementing sustainable practices not only benefits the planet but can also lead to cost savings and improved brand reputation.

Recycling scrap metal, using energy-efficient machinery, and adopting sustainable materials are some of the strategies being employed. Additionally, manufacturers are exploring alternative energy sources to power their operations, further reducing their carbon footprint.

The Impact of Digitalization

Digitalization is transforming how metal fabrication companies operate. From digital twins to IoT-enabled machinery, digital technologies are providing unprecedented visibility into production processes. Real-time data collection and analysis allow for more informed decision-making and predictive maintenance, minimizing downtime.

Conclusion: Embracing Change

The future of metal fabrication is bright, driven by technological advancements and a commitment to sustainability. By embracing these trends, companies can stay competitive and meet the evolving demands of their clients.

The integration of new technologies will not only enhance productivity but also foster innovation within the industry. As we look ahead, it's clear that those who adapt will thrive in this dynamic landscape.